Leno is a weave structure where two or more warp threads twist around the weft threads. This technique is often used to create strong, fine fabric which is stable. The twisted warp yarns ensure the yarn does not move. It is also useful to use this at the edge of a gap in the warp otherwise the warp ends have a tendency to want to fill the space.

Setting up a loom for doup leno is time consuming but once it is set up it’s fairly quick to weave.

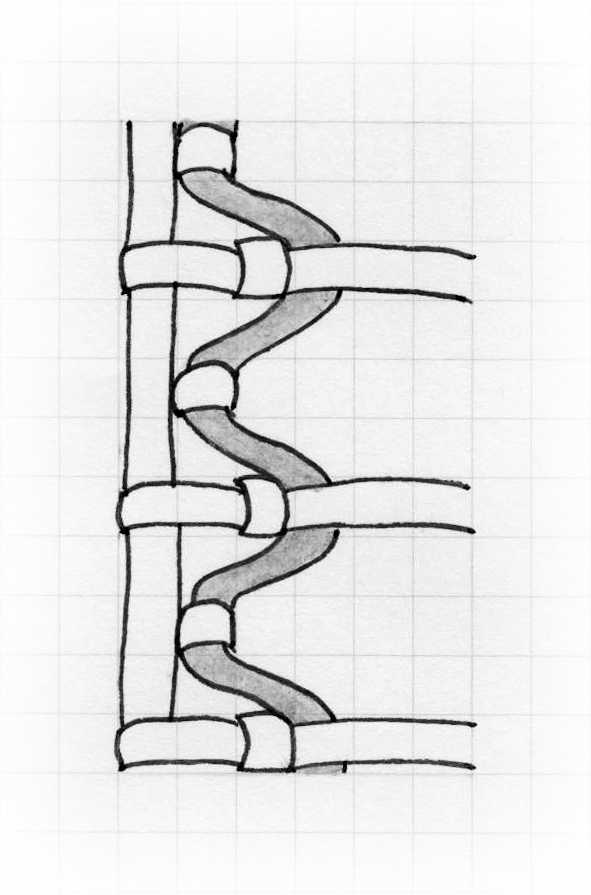

To create this structure a loop of thread (a doup) is attached to an empty shaft and travels through an empty heddle on an adjacent shaft. The doup warp end is then threaded through the doup to pull it under an adjacent warp end creating a twist. A weft pick holds the twist in place.

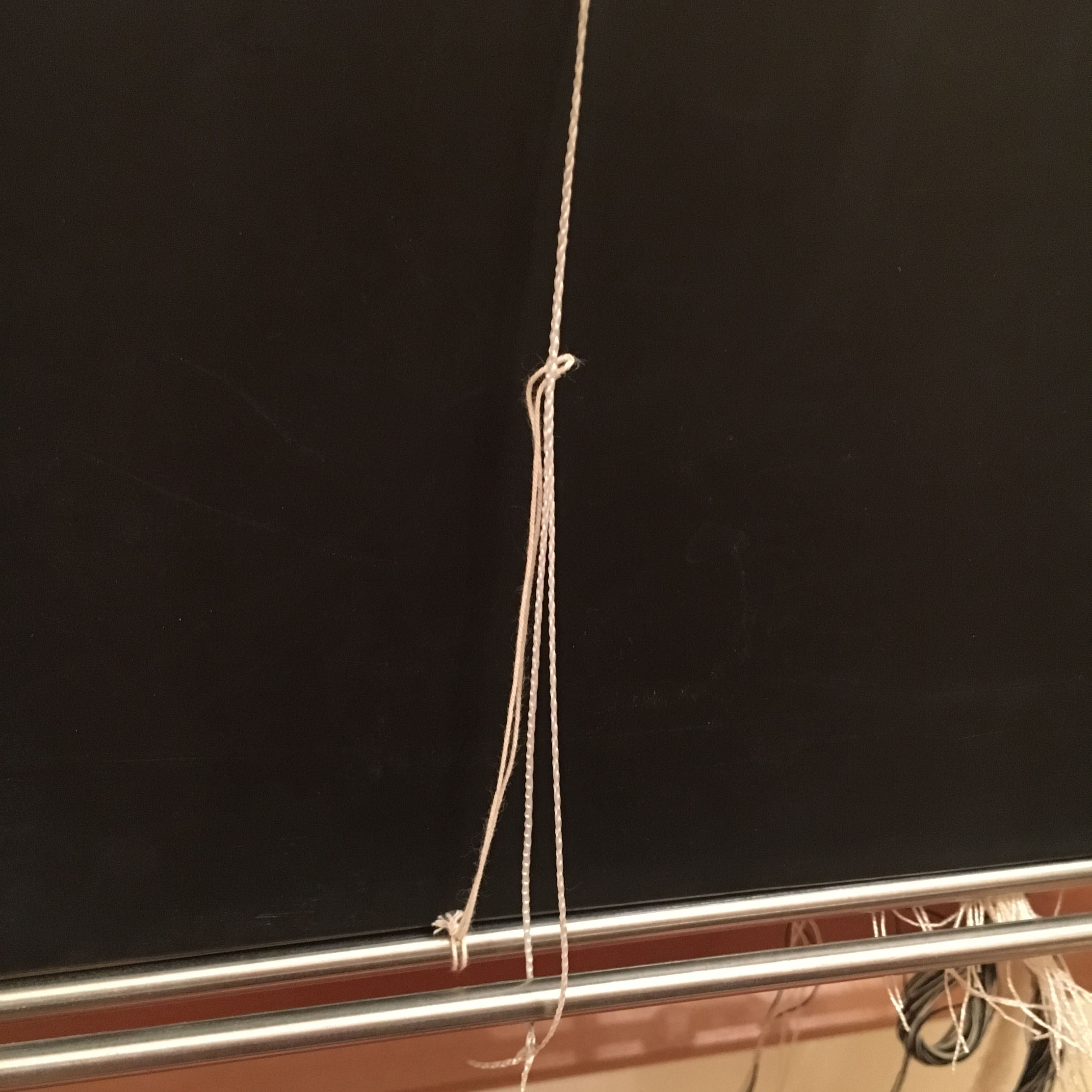

Below shows a doup attached to shaft 2 and poking through an empty heddle on shaft 1. Two shafts are needed to create the twist and two are needed for the twisting warp ends. This is in addition to any shafts needed if other structures are to be included in the fabric. It is important that the doup is not too long and only just reaches through the heddle as this would result in a poor shed. The warp end to be twisted will be threaded through this loop rather than a heddle.

A strong smooth thread works best for the doups. A doup will be needed for every twist required. It’s a good idea to make the doups by tying them around something such as two nails in a piece of wood spaced the required distance apart. They need to all be consistent in length to ensure an even shed.

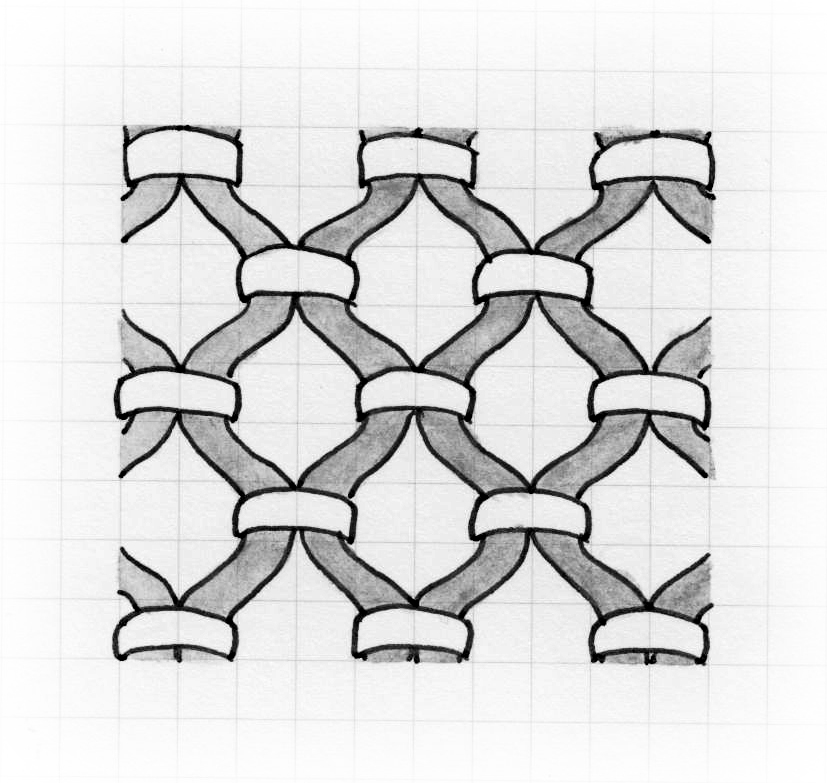

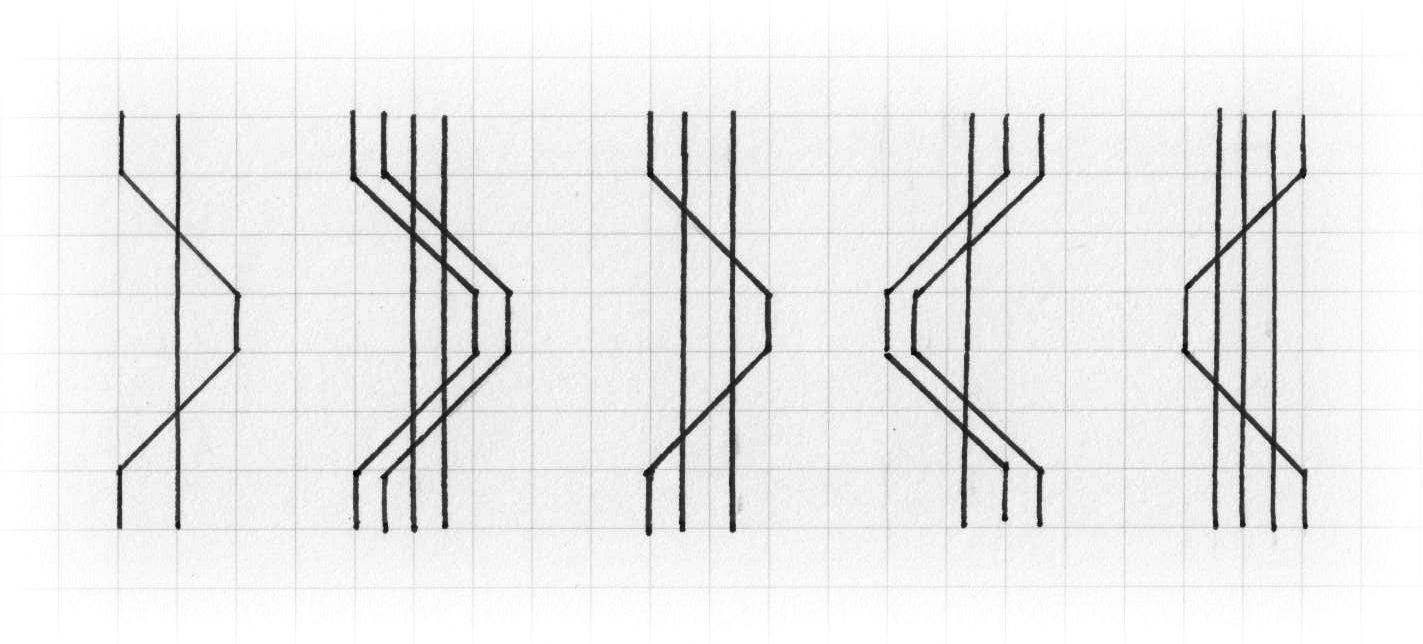

The direction of the twist can be changed and the number of warp ends which twist around each other can be varied. The following shows a selection of options:

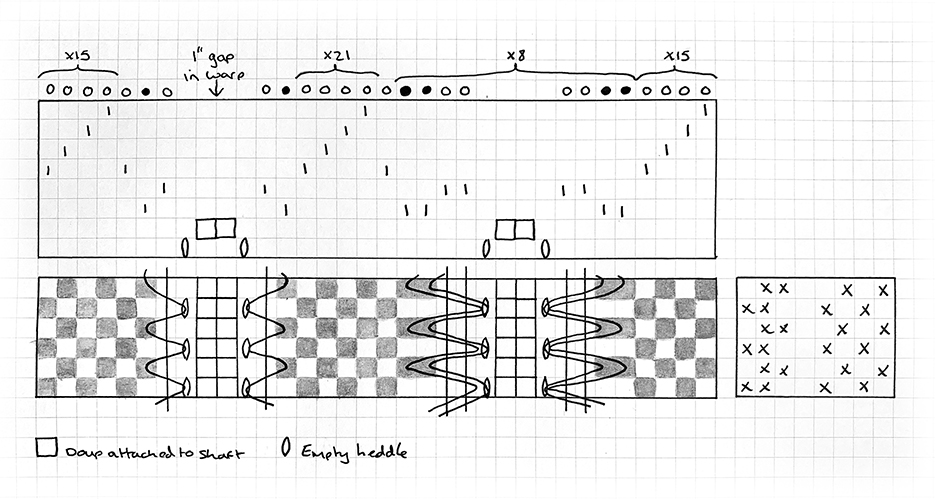

Here is a draft for a weave using doup leno and plain weave structures:

It is important to remember that all the twisting threads (leno ends and warp ends) must be put through the same dent in the reed.

To make it easy to see which warp ends will be twisting these threads are black. All the other threads are white. 8 shafts are used:

Shaft 1 will contain the empty heddle for each doup to be threaded through and will be lifted every time the warp thread is to be twisted.

Shaft 2 is where the doups will be attached .This shaft will need to be kept raised throughout the whole weaving process otherwise the leno warp end may be broken.

Shaft 3 is for the black leno ends which are the ones to be twisted. This will be lowered when shaft 1 is lifted to create the threads.

Shaft 4 is for the warp end that the black end will twist around and remains stationary (lowered) throughout the weaving process.

Shafts 5-8 are used for the plain weave of the rest of the fabric.

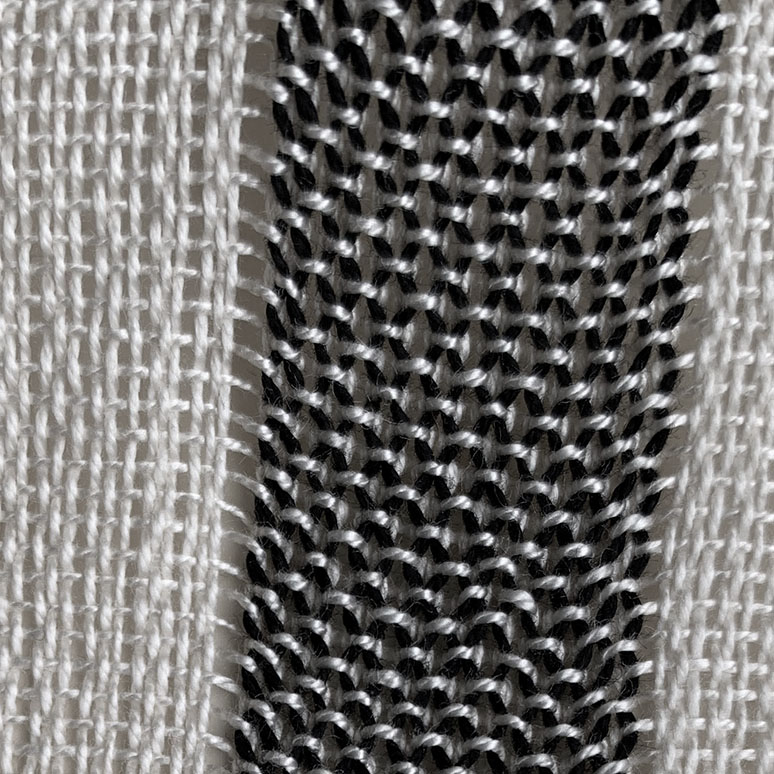

In the draft above there are two sections of Leno on a plain weave fabric. One on the left where just two leno threads are used to stop the warp moving in to a gap in the warp. The second on the right is an area of leno in which two leno ends twist around two warp ends.

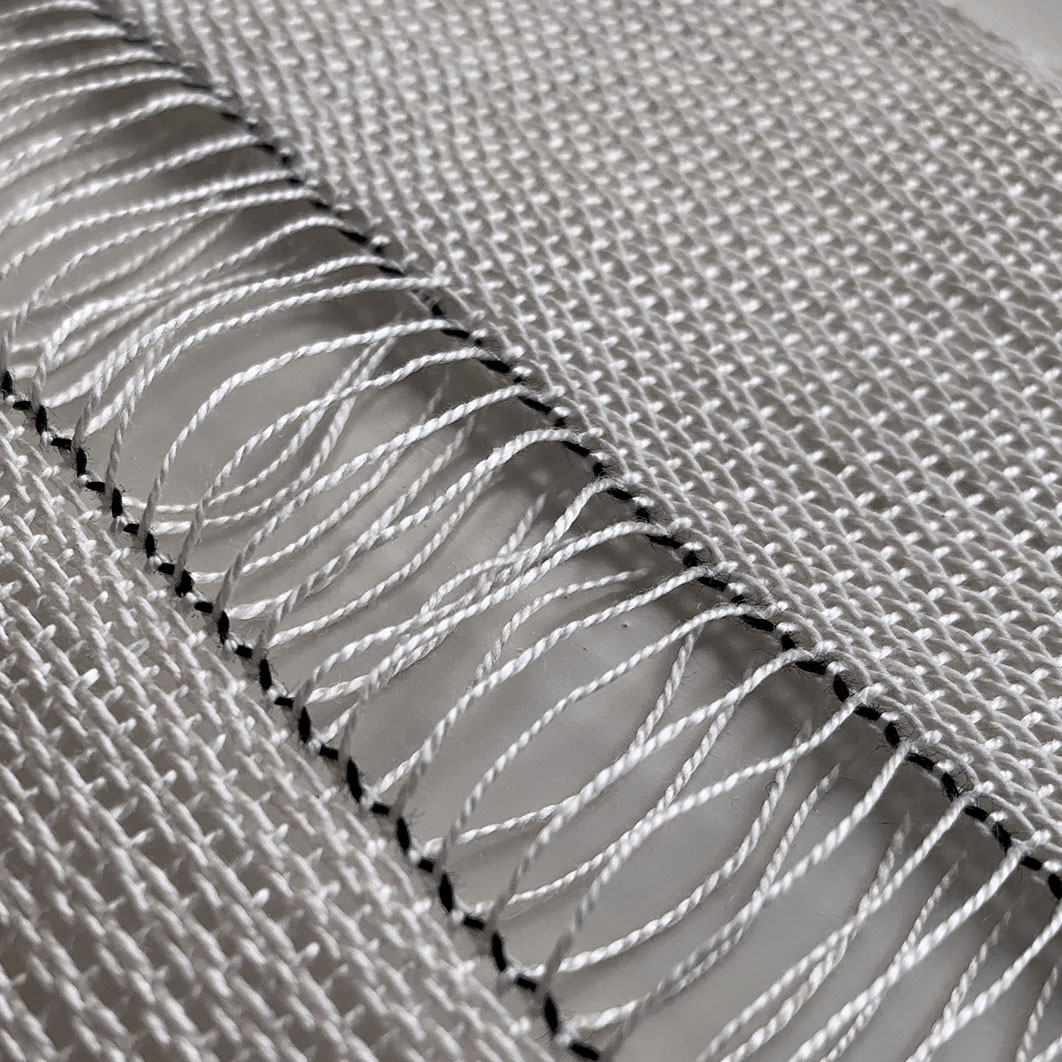

Below are close ups of the two different leno weaves from the above draft as well as a diagram for each to show how the dark leno ends are twisitng.