Making each teddy bear can be a long process which can take up to three weeks in total to complete.

The first step, before weaving commences, is to decide what sort of fabric to weave and what the teddy bear will look like, and then which yarn to use. There is a huge selection of yarn to choose from and getting the right one is important as it will determine the whole look and feel of the finished teddy bear. The make up of the warp need to be considered; Will it all be one colour or type of yarn? How dense will the warp be? How long will the fabric be? How wide do I want it? What sort of structures do I want to weave?

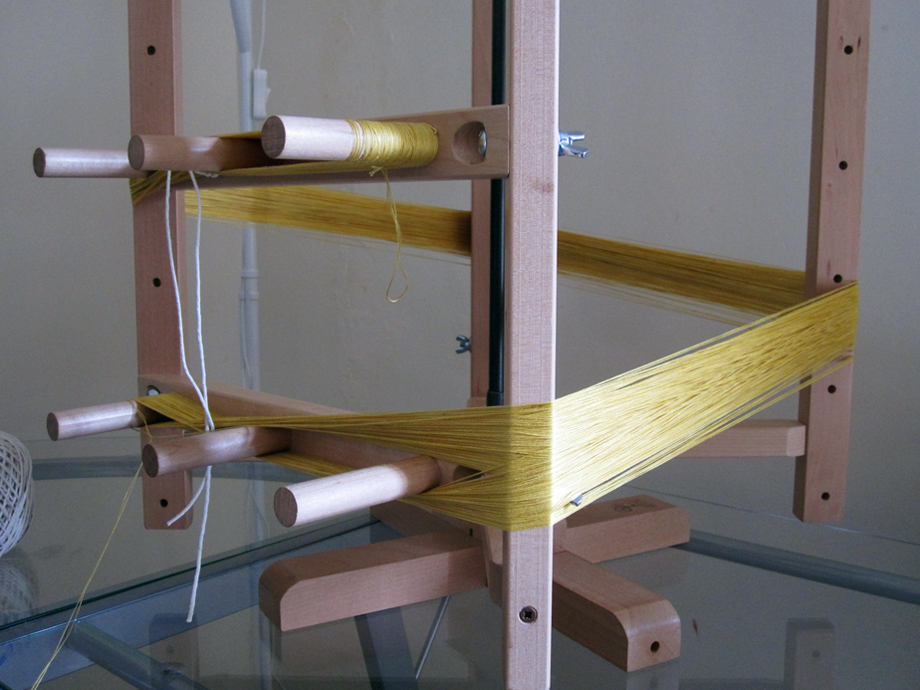

Once these decisions are made the yarn needs to be sorted out. The warping mill enables me to organise my yarn, getting it to the right length, making sure there is enough for the width I want to weave and keeping the yarn untangled.

Below shows a close up of organising the yarn on the warping mill, the yarn has to be sorted in to half inch groups. Here there were 60 ends in every inch, so below I have wrapped the yarn around the warping mille 600 times.

The yarn is now ready to go onto the loom, which can take approximately two days depending on the thickness of the yarn, how thick I want the fabric and how wide/long the fabric is going to be. The half inch groups which were sorted out on the warping mill now get placed on to the raddle and the yarn wound onto the back of the loom, which means when weaving the fabric it will stay the right width and tension.

Each of the 600 strands of yarn is pulled through the eye of a heddle, the heddles lift the strands of yarn during the weaving process enabling me to create patterns. Much consideration needs to go into how they are threaded though as this decides what sort of structures I am going to be able (or not able) to weave.

Here the yarn is being threaded through the reed. Doing this means the fabric will be tightly woven together and kept at the desired width.

To create tension the yarn is finally tied on to the front of the loom. Getting the tension exactly the same throughout the width of the fabric is essential. If it varies then the warp will not weave properly and gaps may appear, yarn can break and the edges will be scruffy.

The yarn is now ready to be woven. Again depending on what sort of pattern, yarn and length of fabric to be woven this can take two weeks. The yarn used in the weft also has to be carefully considered. The colour, thickness and texture will have a huge effect on the look and feel of the final teddy bear.

After the fabric has been woven I then wash the fabric, which improves the look and feel of the fabric. Each teddy bear takes about two days to cut out and stitch together. The pattern pieces are cut out by hand and hand sewn together.

After inserting glass eyes, stitching on his nose and attaching his limbs with cotter pin joints, he can be stuffed. This particular one is filled with glass bead which gives him a lovely feel and good weight.